Design of inductors

If in equipment using induction, the inducer is economically insignificant, design, often overlooked, is nevertheless crucial in finding a solution using this method of heating. The inductor is the "hyphen" between the item to be treated and the generator, the "transmitter" of energy by electromagnetic means.

Careful design can :

Reduce the overall cost of a facility, generating less power (energy saving); mechanical part positioning simplified, reduced number of inductors.

Reduce the overall cost of a facility, generating less power (energy saving); mechanical part positioning simplified, reduced number of inductors. - Reduce maintenance costs by reducing the frequency and duration of response maintenance services to "re settings or replacement of tools, a more rigid design of inductors, non-deformable, to exclude any risk of drift results and adaptation of devices change rapidly.

- Increase of 30, 50 or even 100% productivity with robust tools to increase their shelf life, multiple active inductors parties and / or equipped with magnetic field concentrations to optimize their performance.

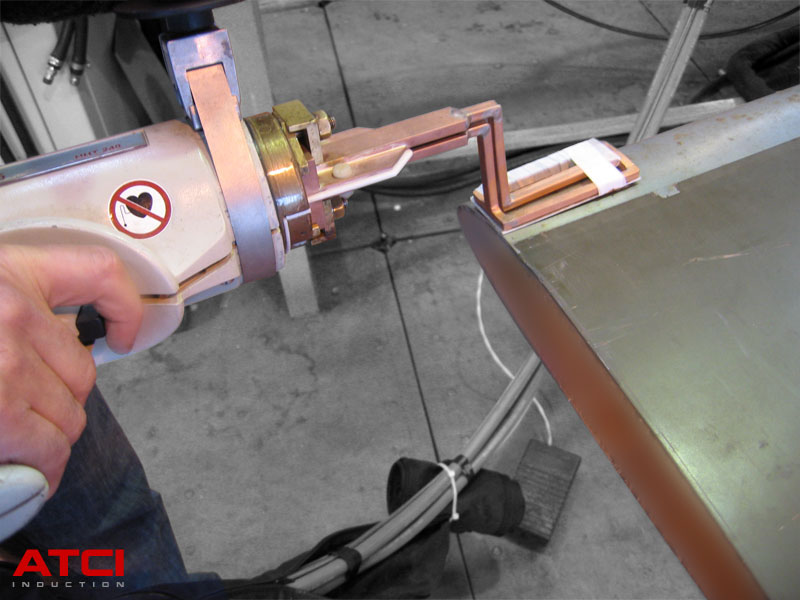

Ensure quality and repeatability of results, first, by the use of mechanical door inducer for the quick and accurate positioning of the inductor, second by the elaboration of inductors fabricated and / or reinforced composites and rigid insulation to minimize scrap and destructive testing.

Ensure quality and repeatability of results, first, by the use of mechanical door inducer for the quick and accurate positioning of the inductor, second by the elaboration of inductors fabricated and / or reinforced composites and rigid insulation to minimize scrap and destructive testing.- Improve operator comfort by integrating ergonomic constraints and safety issues related to electric shock, burns or arcing short circuit. The use of thermal insulation or epoxy coatings to meet these requirements.

Each case is unique.

To meet quality requirements, always more drastic, as part of compliance with labor laws in a difficult economic environment and competitive ATCI is able to offer you a wide range of proven solutions and obviously nurtured by 30 years expertise and proficiency in the use of techniques and new materials.

Developing applications on test platforms.

The validation of solutions requires the completion of testing "size" to verify the feasibility overcome the risk of occurrence of unpredictable problems or not, such as deformation, cracks, overheating, etc. ... The test platform has a large number of generators spanning a wide frequency spectrum from 3 kHz to 1 MHz and 2 kW to 200 kW.

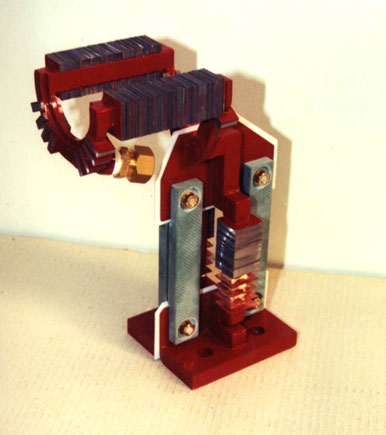

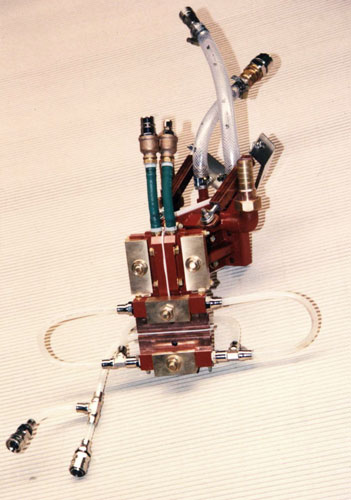

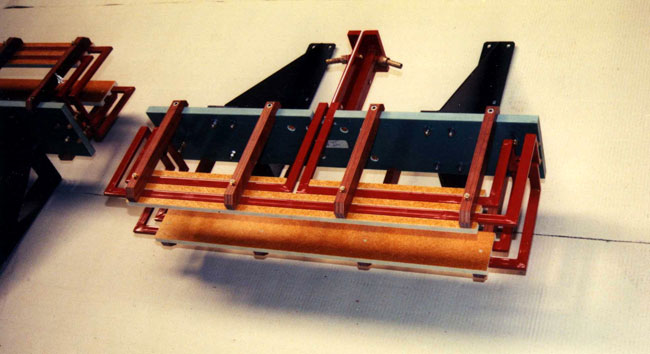

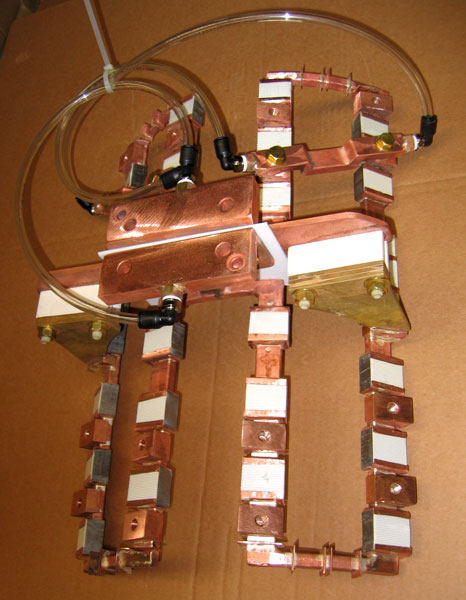

Realization of the inductors.

Developing applications test platform. The perfect knowledge of "living conditions" of inductors and electrical, thermal and magneto which they are subject are taken into account in the production range. The realization of the inductors in our workshop allows each stage of manufacture to ensure quality and guarantee.

Supplies of equipment.

ATCI is able to assist you in developing a specification, the definition and design of a facility, the provision of new or used equipment, supplies of components or specific products

ATCI is able to assist you in developing a specification, the definition and design of a facility, the provision of new or used equipment, supplies of components or specific products

Applications.

ATCI offers expertise in these areas : heat treatment - quenching, tempering, annealing, brazing, heat sealing, shrink fitting, welding, forging and other special applications.

Application Samples

Induction brazing

Example of induction brazing

• Contactors Copper / Cu-W

• Steel Fittings

hardened parts

Example of hardened parts

• Hardening of Internal thread

• Hardening of raceways

hardened parts automotive

Hardened parts for automobile

• Cam Brake

• Rocker

• Tripod